Wyatt Hansen

As a Computer Engineering graduate from Texas A&M University, I have a strong foundation in Embedded Systems and Computer Science. I am eager to join a high-caliber engineering team and apply my skills and knowledge to engineering projects that can make a positive impact on the world.

Engineering Projects

STM32 Robotic Arm Project

3D Printed Robotic Arm with a STM32 micro-controller, integrating a smaller robot as the primary controller using a Super Loop Control methodology. Using STM32 HAL, I mapped the readings of the Potentiometers using the ADC Peripheral to control the servos through a Servo Driver with I2C communication. Credits: YouTube Channel 'Build Some Stuff' - Robotic Arm Design and STL files for 3D Printing, Github User 'Lamik' - PCA9685 Servo Driver for STM32. Check out the code on my GitHub!

Camera and Lidar Data Synchronization

As the Team Lead, I spearheaded my Senior Project, overseeing the successful synchronization and visualization of data originating from a Camera and Lidar in conjunction with the precise PPS signal from an external GPS, a sophisticated process commonly referred to as Sensor Fusion. The project leveraged ROSpy and RViz for advanced data visualization.

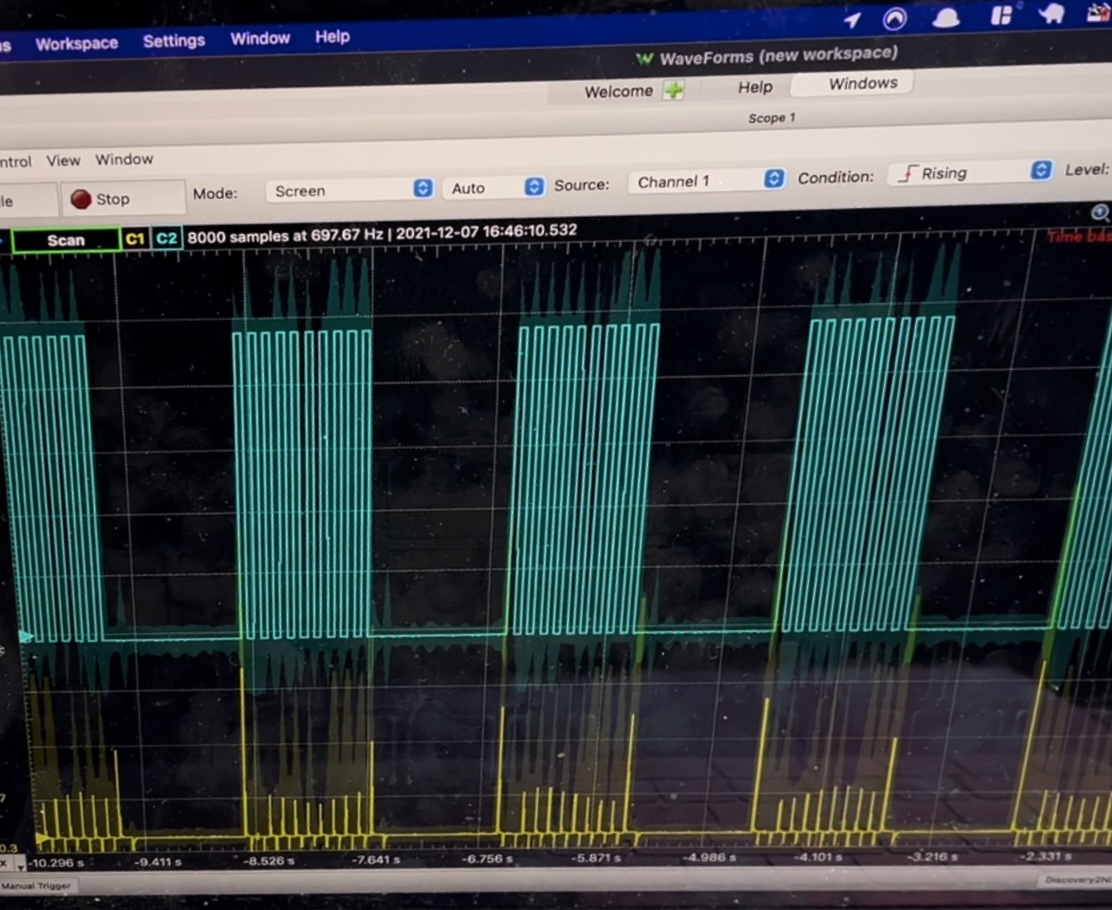

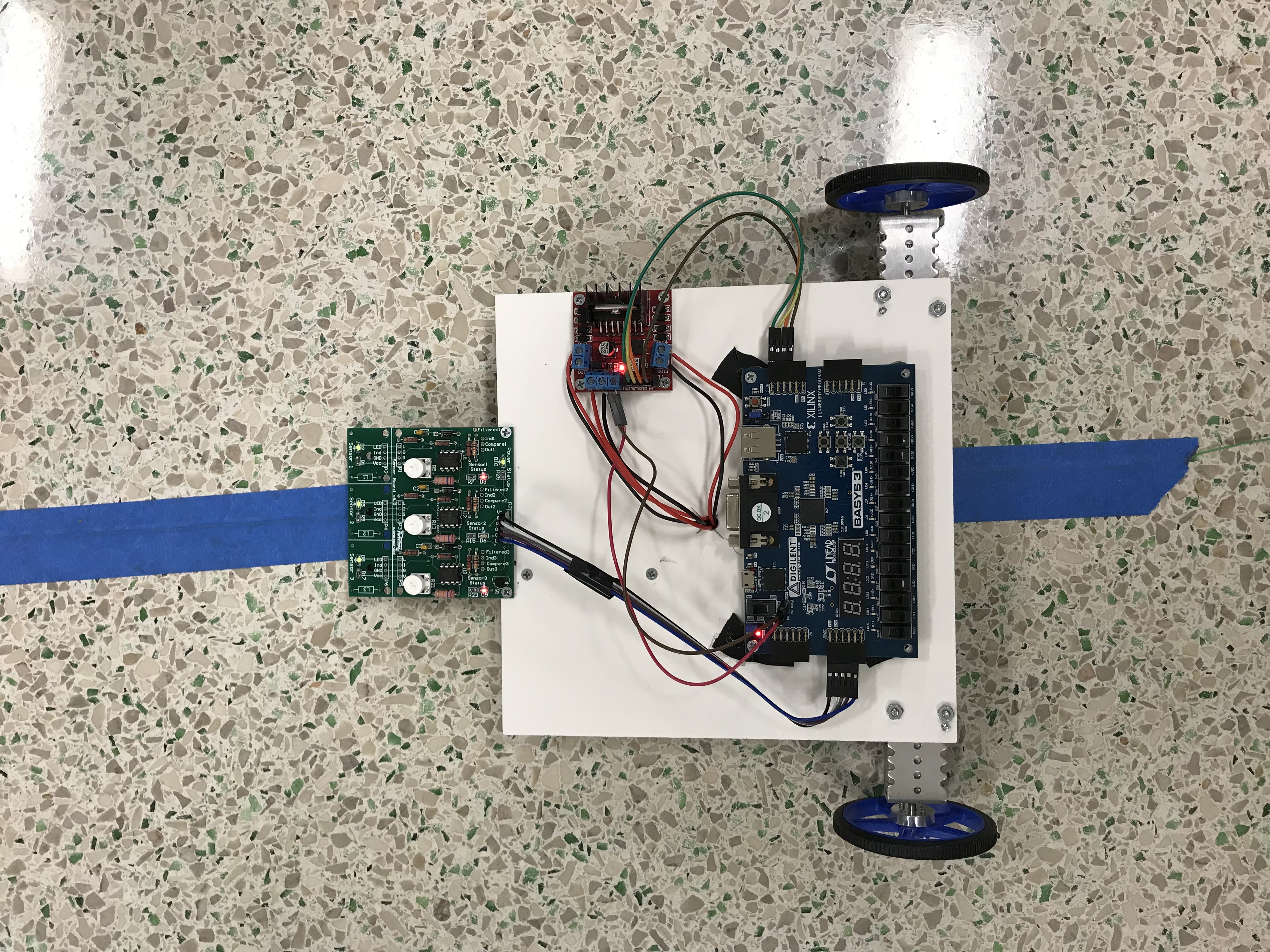

Line Following Robot

Designed and developed an autonomous car utilizing a Xilinx BASYS 3 FPGA, 2 DC motors, and Capacitance Sensors, enabling it to autonomously track and follow a 5V current-carrying wire on the floor. Collaborated closely with a team of two engineering students to successfully complete this project for my Digital Electronics Class.

WiFi Controlled Car

Successfully implementing motor control for four DC motors through the generation of PWM signals via a TI Launchpad CC3200-LAUNCHXL, enabling wireless control over WiFi. A 3D printer was also utilized to manufacture the mechanical frame. Collaborated effectively with a team of four engineering students for the completion of the project for my Foundations of Engineering 112 Class.

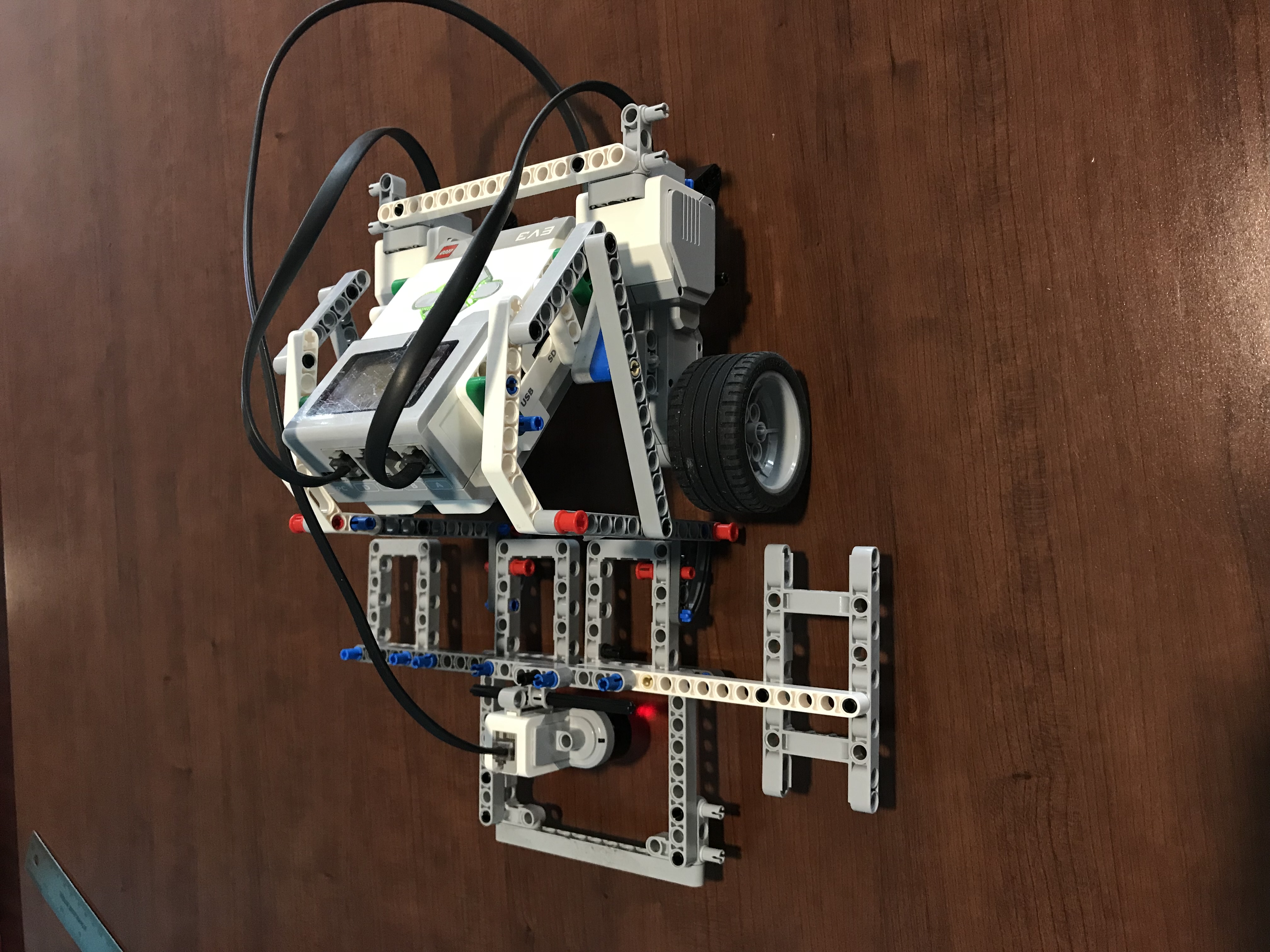

Table Rover

Lego MINDSTORMS EV3 was used to build a Table Rover with an Ultrasonic Sensor to detect the edge of the table and turn with-out falling off. This project was completed as a team of 3 engineering students, for my Foundations of Engineering 111 class.

Personal Projects

Sofle Keyboard

Constructed the Sofle Keyboard as a means to further my expertise in electronics, soldering, and programming. With the keyboard completed my next goal is to develop custom firmware for the keyboard.

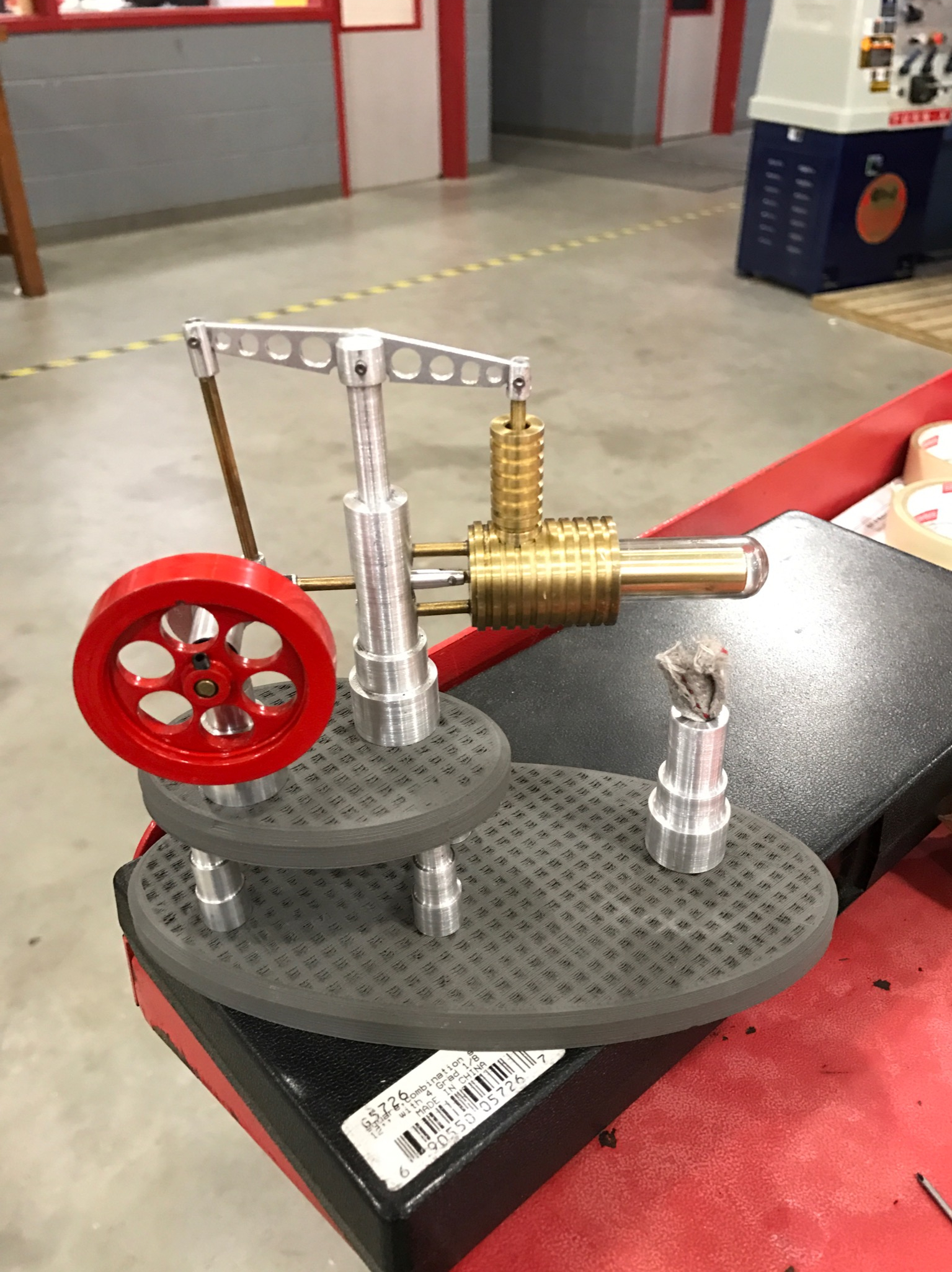

Sterling Engine

In my high school education, I actively participated in Skills USA and this engine achieved qualification for the State Competition in 2017. I meticulously crafted all engine components using a combination of CNC along with manual milling and lathe techniques. Additionally, I excelled in the Manual and Automated Machinist Competition.

Pneumatic Engine

During my high school education, I successfully completed the construction of this engine, which was showcased at the Montgomery County Fair. The project involved the skilled utilization of metal and wood lathes as well as milling equipment.

3D Printed Quad-copter

During my high school education, driven by a passion for electronics and a keen interest in 3D printing technology, I constructed an RC Quad-copter.

Pecky Cypress Epoxy Pebble Foyer Table

I also accomplished the construction of this table, which served as a featured exhibit at the Montgomery County Fair during my high school education. This endeavor encompassed a diverse range of woodworking techniques, tools, and machinery.

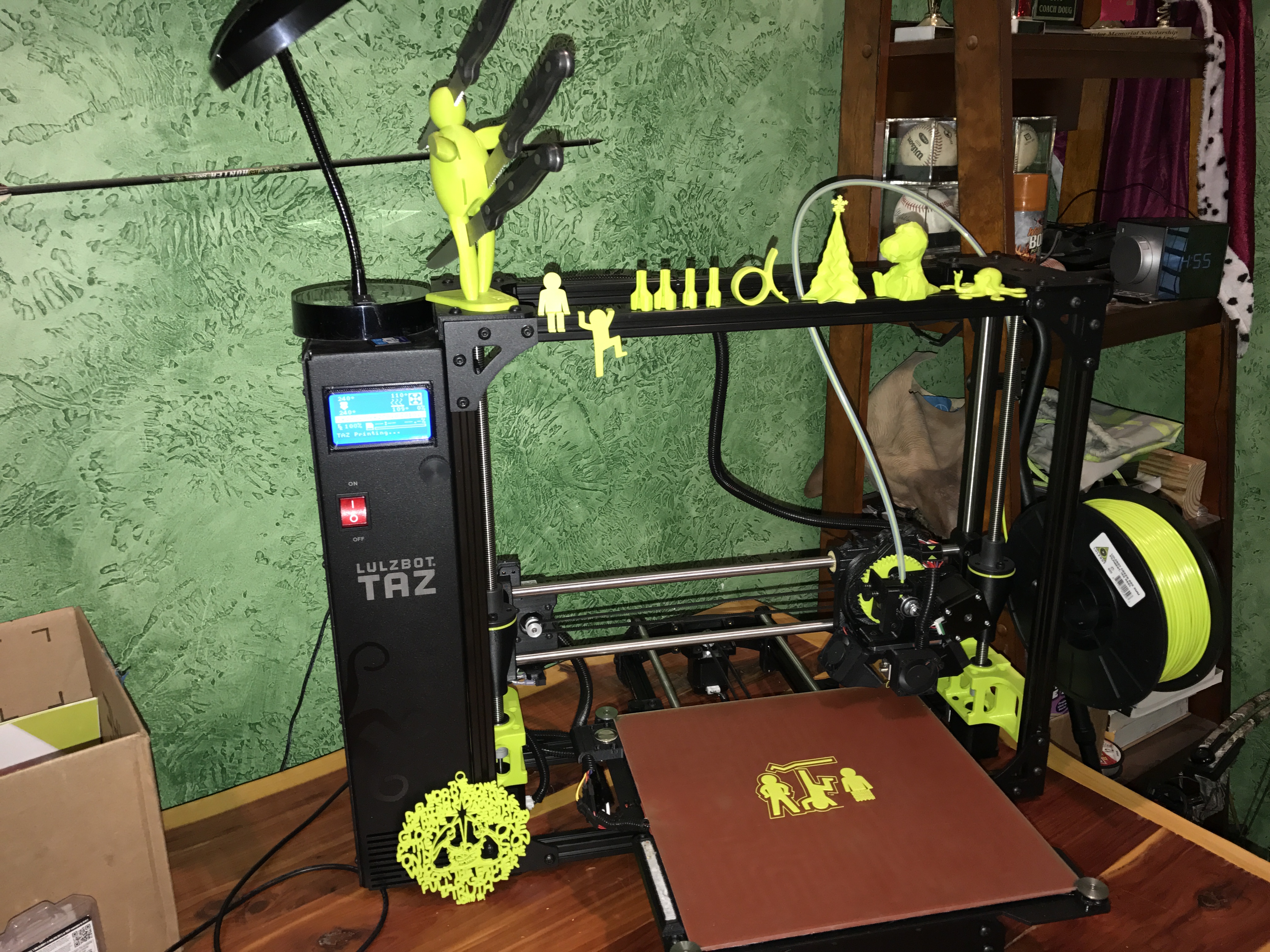

3D Printers

During my high school education, I procured my initial 3D printer, sparking a prolific journey of creating numerous models and prints using CAD software.

Experiences

Genesis Dimensions

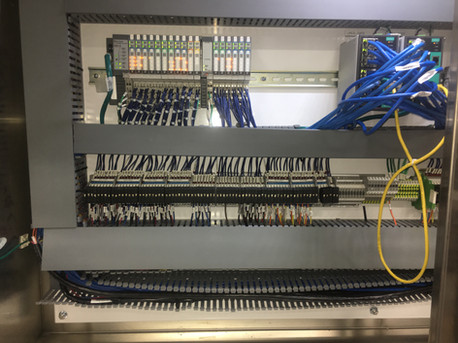

As an Engineering Intern, I achieved the successful installation and deployment of Taiga, an open-source Agile project management tool, on in-house servers, significantly elevating project coordination and management capabilities. Additionally, I provided valuable support in the manufacturing and integration of industrial control panels for a Kuka Robot and a Material Flow Control System.

Arrington Automation

As an Engineering Intern I collaborated with a team of engineers to contribute to the design, testing, manufacturing, and integration processes of control panels for industrial control systems.

BUILD

During my dedicated three-year tenure as a volunteer with Build, I held the pivotal role of Design Command Team Leader and was an integral member of the Construction Command Team. Build is a student-led philanthropic organization dedicated to the construction of medical clinics in third-world countries, fostering unity and purpose within the student body.

Diplomas & Certifications

Computer Engineering and Cyber Security

Completion of my Bachelors in Computer Engineering with a Minor in Cyber Security - From Texas A&M University Graduating Class of 2021.

Associates General Education

This Associates was completed in 2017 while I was enrolled in an Early College program during High School from Lone Star University.

Mastering Microcontroller and Embedded Driver Development

I completed this course using a STM32 Nucleo F446RE Board and aquired a comprehensive understanding of Driver Development, Peripheral IRQs/Vector table/NVIC interfaces, AHB & APB bus protocols, and MCU Peripherals such as GPIO, SPI, I2C and USART.

Mastering RTOS

I completed this course using a STM32 Nucleo Board and aquired a comprehensive understanding of RTOS principles, encompassing key concepts such as Tasks, Scheduling, Semaphores, Queues, Mutexes, Context Switching, and advanced debugging techniques employing SEGGER SystemView.

Embedded Systems Programming on ARM Cortex-M3/M4 Processor

I completed this course using a STM32 Nucleo Board and aquired a comprehensive understanding of Embedded Systems principles, encompassing key concepts such as C, Inline Assembly, Bus Interfaces, NVIC, Exception Handling, IRQ, and implemented a task scheduler using Round Robin Prioritization, PENDSV and SYSTICK.